At Aston Fittings, we pride ourselves on delivering the highest quality components for fluid control and instrumentation systems. With decades of experience in precision engineering, our stainless steel manifolds stand as a testament to our commitment to performance, reliability, and safety across industries.

Whether you require a bespoke solution or a standard configuration, our manifold systems are crafted to meet the most rigorous demands of pressure and performance.

What Are Stainless Steel Manifolds?

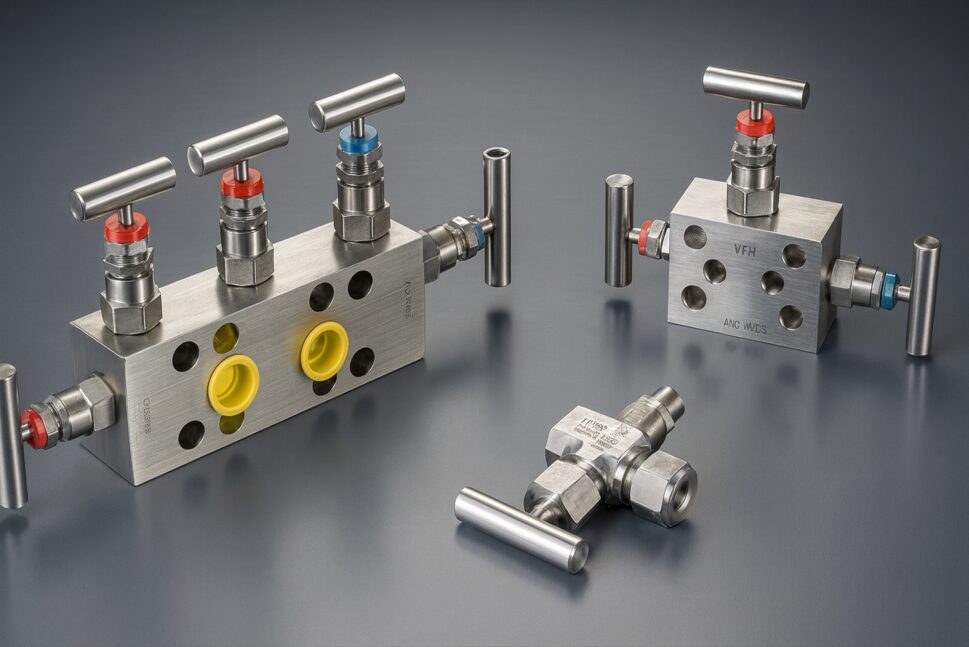

Stainless steel manifolds are key components in controlling the flow and direction of fluids or gases within complex systems. Typically used in industries such as petrochemical, pharmaceutical, food and beverage, and industrial processing, manifolds allow for the efficient and safe distribution of media across multiple lines.

Our stainless steel manifolds serve as the backbone of countless fluid control systems, offering compact, corrosion-resistant, and durable solutions that outperform traditional pipework assemblies.

Why Choose Our Stainless Steel Manifolds?

Our manifolds are manufactured to exacting standards using premium-grade stainless steel, including 316 and 316L varieties. These materials are renowned for their resistance to corrosion, even in the harshest environments involving high pressures, temperatures, or exposure to chemicals and saline.

Here are just a few of the reasons why clients across the UK and Europe trust Aston Fittings for their manifold solutions:

Superior Material Quality

We only use stainless steel of the highest quality to ensure longevity, durability, and safe operation. Our products are designed to handle extreme conditions, offering high tensile strength and outstanding resistance to pitting and crevice corrosion.

Versatile Applications

From test and measurement instrumentation to process control in chemical plants, our stainless steel manifolds are adaptable to a wide range of applications. Whether you require a 2-way, 3-way, or 5-way valve configuration, or need a custom-built assembly, we provide solutions that deliver exact control and seamless integration.

Precision Engineering

Our components are CNC-machined to tight tolerances to ensure leak-proof, vibration-resistant performance. Each manifold is rigorously tested to meet international pressure standards, giving you peace of mind that your system is both safe and efficient.

Corrosion Resistance

Unlike brass or carbon steel alternatives, stainless steel manifolds offer excellent resistance to environmental and chemical corrosion. This makes them ideal for installations in marine, offshore, and highly regulated cleanroom environments.

Custom Design Capability

We understand that no two applications are exactly alike. That’s why we offer bespoke manifold manufacturing services, working closely with engineers and project managers to develop tailored solutions. Whether you need custom porting, unusual connection threads, or integration with specific fittings, our in-house team is here to support your project from concept to completion.

Wide Range of Manifold Configurations

We offer a comprehensive selection of stainless steel manifold valves and accessories, including:

- 2-Way Manifolds – Ideal for isolating pressure instruments

- 3-Way Manifolds – Commonly used for differential pressure transmitters

- 5-Way Manifolds – Allow for equalising and venting in complex systems

- Block & Bleed Manifolds – Enable safe calibration and maintenance without disrupting operations

- Modular and Compact Systems – For space-saving installations in restricted environments

All configurations can be supplied with NPT, BSPP, BSPT, and metric threads, as well as DIN and ANSI flange options where required.

Industries We Serve

Our stainless steel manifolds are trusted by a wide variety of industries, including:

- Oil & Gas

- Pharmaceutical Manufacturing

- Food & Beverage Processing

- Water Treatment

- Power Generation

- Chemical and Petrochemical Plants

Our ability to provide robust, high-performance manifolds with fast lead times has made us a preferred supplier for both OEMs and maintenance contractors.

Commitment to Quality and Service

At Aston Fittings, quality is never compromised. Every stainless steel manifold we produce undergoes strict quality checks, including hydrostatic pressure testing and material traceability documentation, ensuring compliance with ISO 9001 and PED regulations.

In addition to our quality products, we also pride ourselves on exceptional customer service. Our technical team is on hand to provide expert advice, assist with specifications, and offer guidance on best practices for installation and maintenance.

One-Stop Shop for Stainless Steel Fittings

Our stainless steel manifolds are just one part of a vast product offering. As specialists in fluid and gas control systems, we stock an extensive inventory of related components, including:

- Tube fittings

- Pipe fittings

- Compression fittings

- Flanges and adaptors

- Valves and instrumentation fittings

This allows us to provide a complete, compatible solution for your pipeline or instrumentation system, saving you valuable time and ensuring a seamless procurement process.

Fast Delivery and Reliable Supply Chain

We understand the importance of uptime and rapid response. That’s why we maintain a large stock of standard manifolds and fittings at our UK-based warehouse, ready for immediate dispatch. Our strong supply chain and logistics partnerships mean you can count on us for timely delivery across the UK, Europe, and beyond.

Let’s Build Your Solution

If you are looking for premium stainless steel manifolds backed by technical expertise and responsive support, look no further. Whether you’re designing a new system or upgrading existing infrastructure, we’re here to help.