As fire protection technology continues to evolve, watermist fire suppression systems are taking centre stage as one of the most efficient, environmentally responsible and versatile solutions available.

At Aston Fittings, we work closely with engineers, installers and manufacturers who rely on precision components to build these systems and we’ve seen first-hand how watermist technology is transforming fire safety across a wide range of sectors.

What Are Watermist Fire Suppression Systems?

Watermist fire suppression systems operate by dispersing incredibly fine water droplets, typically less than 1,000 microns in diameter; Because these droplets are so small, they respond differently to heat and fire compared to traditional sprinkler systems.

As the mist reaches high temperatures, the droplets evaporate rapidly, removing heat from the fire and cooling the surrounding air. At the same time, these droplets displace oxygen in the immediate vicinity, helping to extinguish the flames and prevent re-ignition.This dual mechanism makes watermist exceptionally effective.

The fine mist can also reach areas that conventional sprinklers struggle with, such as confined spaces or areas shielded by machinery or structural features. Additionally, because the system uses water in such small quantities, it dramatically reduces the risk of water damage during and after the sprinklers activation.

Why Watermist Systems Are Gaining Momentum

Modern fire protection must do more than simply extinguish flames. It must protect life, safeguard assets, support business continuity and avoid unnecessary environmental impact. Watermist technology has been engineered specifically to meet all of these expectations.

One of the most significant advantages of watermist fire suppression systems is their ability to suppress a fire quickly. The speed at which the mist cools the fire and reduces the temperature makes it exceptionally effective at stopping the spread. Whether in a residential kitchen or an industrial plant room, this fast suppression can be the difference between a contained incident and extensive damage.

Another major appeal of watermist fire suppression systems is that they use substantially less water compared to traditional sprinkler systems. By releasing microscopic droplets instead of large volumes of water, watermist fire suppression systems achieve the same; and often better; levels of suppression while using a fraction of the water of standard systems. This is particularly important in areas that contain sensitive materials, such as archives, data centres, medical facilities or locations where water damage would cause significant disruption.

Watermist systems are also environmentally responsible. Since they rely solely on water, they produce no toxic by-products, no chemical residue and no long-term environmental harm. In a world increasingly focused on sustainability and responsible building management, this makes installing watermist fire suppression systems a forward-thinking choice for your property.

Safety during activation is another crucial factor. Traditional gas-based fire suppression systems can pose risks to occupants when discharged. Watermist systems, however, are completely safe for people, as water is non-toxic and does not displace oxygen significantly throughout an entire room. This makes them well suited to buildings where occupants may need to remain in place during part of the evacuation or where staff are present around the clock.

Our Role in Supporting Watermist Systems

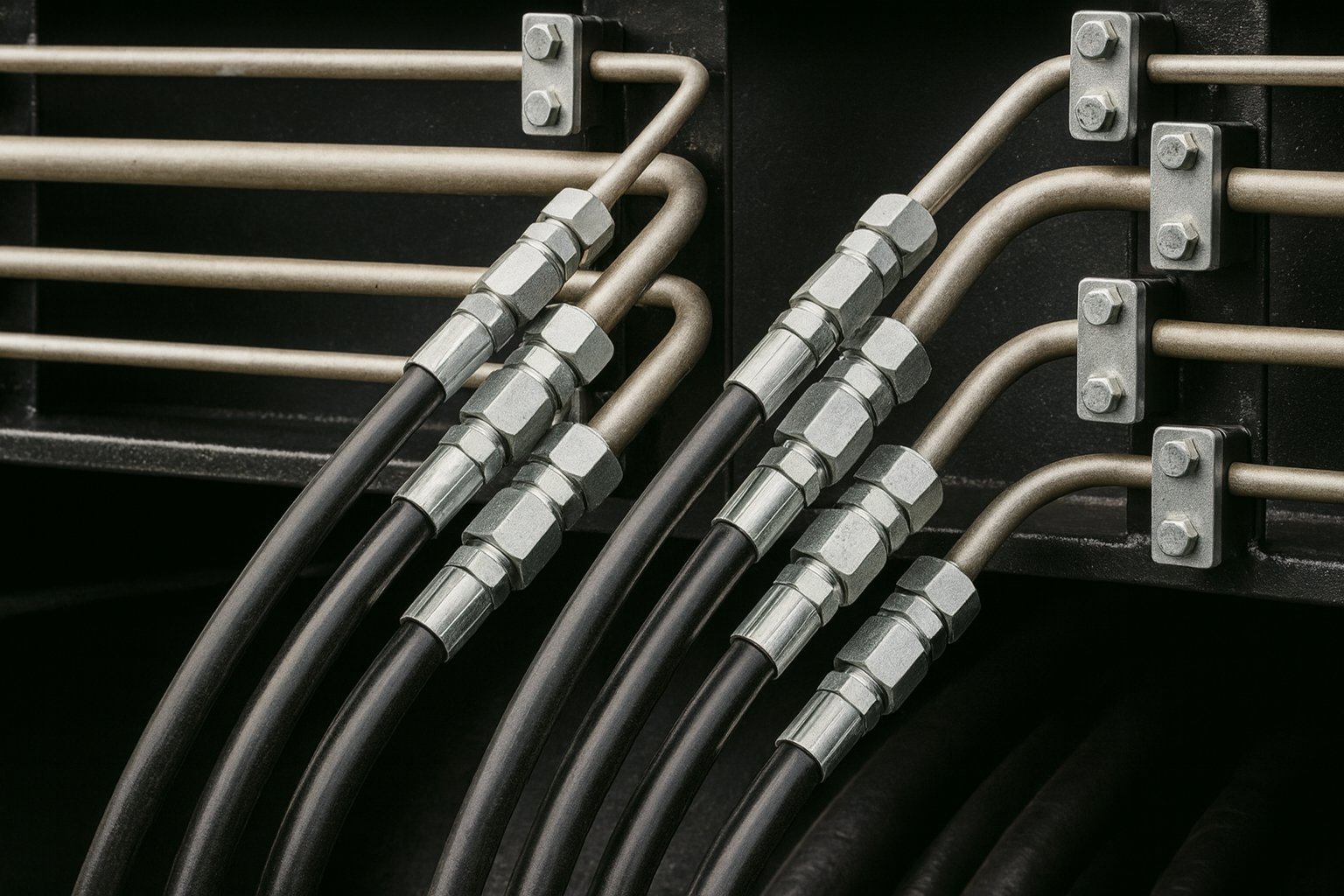

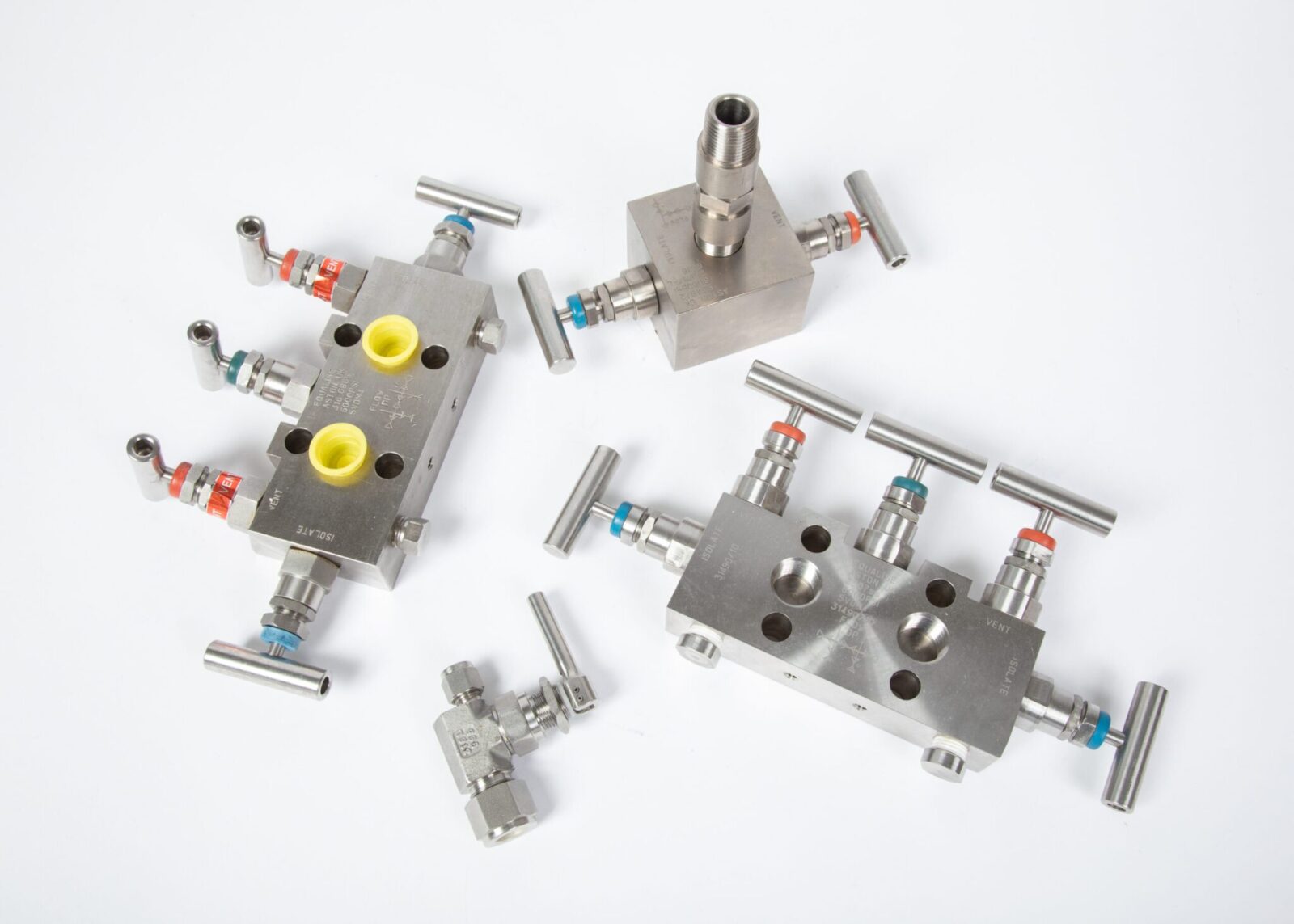

At Aston Fittings, our primary focus is on manufacturing high-quality products, from pipe fittings, valves and flanges to bespoke stainless-steel components: all of which are elements that form the backbone of many watermist fire suppression systems. These systems operate under carefully controlled pressures, making the reliability of their components essential. The high-quality components we supply help ensure that every droplet is delivered precisely where it needs to be; giving you peace of mind that should the worst occur, your system should hold up to the challenge.

Furthermore, our expertise allows us to support both standard requirements and bespoke solutions. Whether a project calls for specialist stainless-steel fittings, custom adaptors or durable pipework that can withstand demanding conditions, our team can work alongside system designers and installers to achieve dependable results. Fire suppression systems, especially those using watermist technology, cannot afford weak points: which is why precision engineering matters.

A Smarter Approach to Modern Fire Protection

As businesses, property owners and safety professionals plan for the months ahead, watermist fire suppression systems continue to stand out as one of the smartest, most adaptable and most environmentally conscious choices available for your property’s safety: They reduce fire damage, lessen the impact of downtime, minimise environmental harm and offer excellent protection for both people and property.

At Aston Fittings, we’re proud to contribute to this growing area of fire safety innovation by supplying the essential components that make these systems work effectively. As more buildings adopt advanced fire suppression solutions, watermist technology is sure to play a central role in shaping the future of fire protection.

If you’re interested in how our bespoke component manufacturing solutions can be incorporated into your properties’ watermist fire suppression systems, get in touch with our expert team today for more information.